A concrete curing compound is a material used for retaining the moisture inside the concrete to prevent it from getting hardened. There are specialized chemicals available in the market for the curing of concrete compounds.

The concrete curing agents help in avoiding the cracks inside the concrete once it is being applied on the surface. Also, it prevents early drying of the concrete.

Table of Contents

The concrete curing compound agents are essential to be added into the mixture of the cement as retaining the moisture inside the concrete is necessary for the concrete to get set on the structure and to prevent early drying or creating gaps inside the concrete.

There are various products related to concrete curing compounds being manufactured by Sakshi Chem Sciences Pvt Ltd which has various applications to be used in concrete curing compounds.

The products are manufactured at our state-of-the-art manufacturing facility in Nagpur, Maharashtra. The curing products are used in the construction of highways, roadways, bridges, and airport runways. etc.

The concrete after mixing and applying on the surface should not dry up very quickly as in other cases the plaster may get damaged or else cracks may develop on the surface. Thus, the use of curing compounds is very much essential for the long-lasting life of the structure.

There are various products available in the market for the curing of compounds, but chemical-based compounds are the most effective compounds for the curing of concrete. The products of the curing are available in two types of the liquid membrane curing compound and wax-based curing compound.

These products provide a protective barrier on the concrete surface. As technology is improving in every field it is essential to make use of chemicals for the better-quality construction of infrastructure projects. Chemicals can play a vital role in the development of the structures and provide a long life to the structures.

Benefits of the concrete curing compounds:

- Prevents cracks: The curing compounds help retain the moisture inside the concrete and thus the concrete retains moisture when applied on the surface and prevents cracks from developing on the structure.

- Helps in moisture retention: The cement concrete requires moisture into the concrete for better curing. The curing takes a few weeks or sometimes even months to get hardened. Thus, the curing compound chemical helps in water retention inside the concrete mixture to yield better quality results.

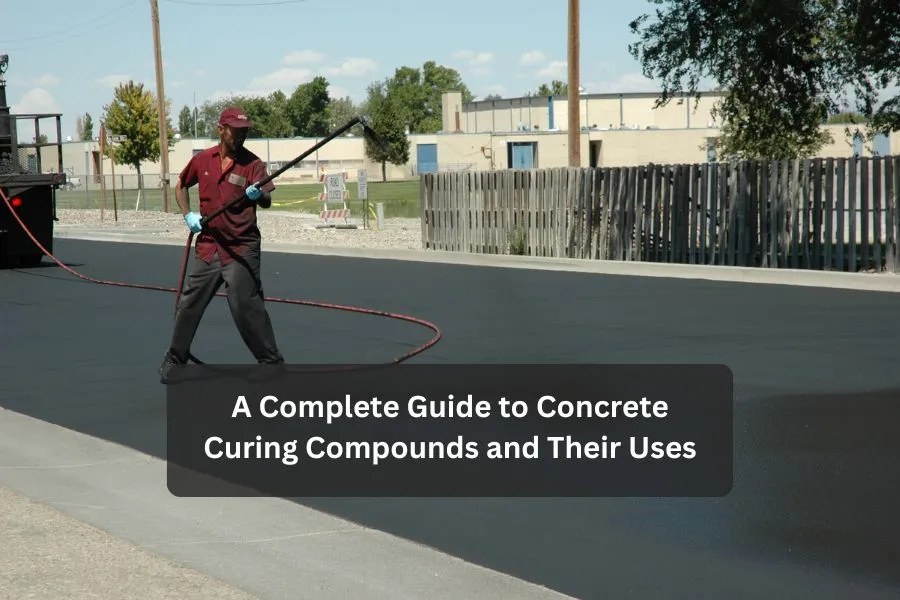

- Large area applications: The curing compounds are used for wide structures wherein water curing is not possible. Chemical curing is done with the help of spray pumps over the highways, airport runways, or large-sized factory premises flooring.

- Saves water: The curing compounds are highly recommended in drought-prone areas or areas that have a shortage of water. Also, the remote sites where transporting water is difficult like for highway construction then in that case the use of curing compounds is beneficial. The curing compounds help save water as moisture can be retained inside the concrete when these chemicals are added to the concrete.

- Enhanced durability: Proper use of chemicals in the concrete mixture helps in longer durability of the concrete. It also helps in increased resistance to abrasion and avoids scaling over the surface of the structures.

- Environmental conditions: At the construction site if there is an excessively hot & dry climate then in that case the concrete may get hardened very easily. Thus, in that case, the curing compounds help in retaining moisture inside the concrete. Also, if there are excessive winds then the chances of concrete getting dried up increases. Thus, in that case, the concrete becomes dry faster thus the use of curing compounds is beneficial. India being a tropical country has a hot climate in the majority of the months due to which the use of curing compounds can be done widely in case of the highway’s construction.

- Cost-effectiveness: The curing, if done with the help of water, may lead to higher costs as a huge quantity of water is being used at the construction site for curing which becomes very expensive. Thus, the use of curing chemicals is beneficial for cost optimization as these curing chemicals are required to be added in very small proportions thus saving the transportation cost.

- Helps in better quality of structures: The use of curing compound chemicals helps in developing better quality construction as the structures retain moisture which helps in better curing. While as curing with the help of water may not be that efficient if there is a delay in curing by the labor. Thus, in the case of the use of chemicals, there is an assurance of moisture retention in the concrete.

What is curing? Why is curing necessary?

Curing is the process of maintaining moisture in the structures either using chemicals or else by water. Curing is essential in the case of any of the concrete structures as the structure becomes stronger and the compressive strength of the structure increases.

Also, the curing helps in avoiding cracks in the structures. Thus, after applying/pouring concrete it is very much essential to do the curing of the structure.

Types of curing compounds:

The curing compounds are of various types with varied features. Below is the product range being manufactured by Sakshi Chem Sciences Pvt Ltd:

- Addage BondCote CC [Wax-based]: The Addage Bond cote is a wax-based product in which the moisture retention is high in the concrete mixture. The product also helps in reducing permeability and produces durable and dust-free surfaces. The product reduces shrinkage in the structure and retains moisture in the structures.

- Addage bondCote CCARB [Aluminium resin based]: The Addage bond Cote CCARB is a water-based curing compound. This product is designed in such a way that it is easy to apply and use. The liquid chemical needs to be sprayed on the cement surface which helps reduce the shrinkage, prevents moisture loss and avoids developing cracks in the structure.

- Addage bondCote CCARB [Solvent-based]: This is a solvent-based chemical compound for the curing of concrete. It can be sprayed over the surface or else can be applied with the help of a brush to retain moisture. This product effectively helps in curing concrete.

Conclusion:

Thus, concrete curing compounds are of great use as they help retain moisture in the concrete. Retaining moisture is essential in the structure to make the structure hard, durable, and free from cracks. Also, the compressive strength of the concrete increases when the curing is proper.

This product is highly recommended to be used during the summer season as the temperatures are high and evaporation levels are also high. Thus, the evaporation of water from the concrete mixture increases, due to which shrinkage may happen.

Also, there is a shortage of water in the summer season in most of the regions even in that case the use of curing chemicals is more beneficial than using water for curing.

Found the blog informative? Do share it with your friends.