Over the past few years, Reinforced Autoclaved Aerated Concrete (RAAC) has gained attention for all the wrong reasons. Once touted as a progressive and innovative architectural construction material, it is now undergoing scrutiny and matters of safety as aging buildings come to the forefront.

Let’s take a moment to consider what RAAC is, why it is so widely utilized, and what has prompted the current slew of concern.

Table of Contents

What is Reinforced Autoclaved Aerated Concrete?

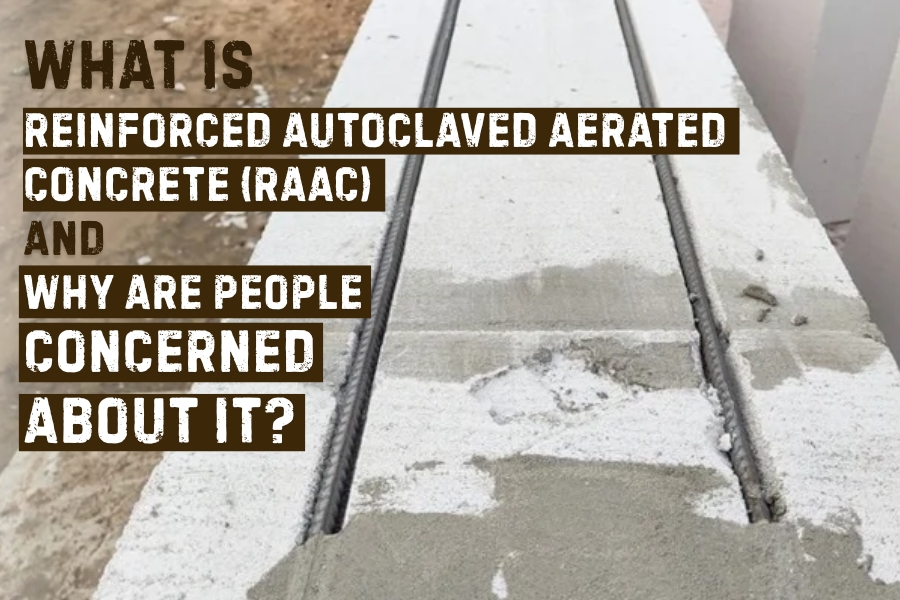

Reinforced Autoclaved Aerated Concrete (RAAC) is a lightweight style of concrete that was developed after World War II. It became a popular choice for schools, hospitals, and office buildings across the UK and Europe as it was cost-effective, easy to handle, and provided exceptional insulation.

Unlike reinforced concrete, which typically contains coarse aggregates such as gravel or crushed stone, RAAC does not contain coarse aggregates. Instead, RAAC contains a bubbly, aerated structure, which is achieved through including a foaming agent during production.

This material characteristic permits the lightweight and thermal efficiency properties of the concrete, but it also creates a very different internal structure, which, ultimately, results in a different strength of concrete.

Although reinforced concrete is compact and extraordinarily durable, RAAC – designed to be more porous – is easier to transport and install, and also more susceptible to water, temperature alterations, and deterioration over time.

Why was RAAC a concern?

RAAC has been regarded as a good alternative for traditional concrete for many years, even as a relaxation for non-load-bearing applications. However, in the late 1980s, after many years of experience, engineers and safety professionals began to raise concerns about RAAC’s longevity in terms of strength and stability.

The main issue is related to do with age and aging materials. RAAC can be weakened by water exposure, temperature changes, and carbonation caused by the chemical reaction between CO2 in the atmosphere and the free lime within the mix.

The corrosion of internal steel reinforcement, or rebar, occurs when the material fails. When this happens, the concrete sheets or panels can lose their structural integrity with little or no warning.

Many buildings employing RAAC are now 40 to 60 years old, which is well beyond the life expectancy of RAAC – some indication 30 years is expected.

This has grown fears of potential structural failures, particularly in public buildings, where public safety and possibly litigation are always a concern. In some cases, there were situations where parts of a building or structure were closed off or sealed after RAAC panels were discovered to be deteriorating.

Factors Affecting the Strength of RAAC

The quality of concrete is dependent on its makeup, the conditioning of curing, and the conditions under which it was exposed. For RAAC, there are no coarse aggregates, which means that it will, without exception, always have lower compressive and tensile strength than standard concrete.

Moisture is another significant factor, as it can pass into the air pockets of the RAAC and cause a lower load-bearing capacity. Studies have shown that after short-term exposure to moisture while the RAAC is subjected to pollution and humidity, it has led to a 10% reduction in the strength of RAAC. Even prolonged exposure has been shown to exacerbate RAAC degradation.

Flat roof panels made with RAAC are also subject to additional concern. Rain or pooling on the flat surface would certainly lead to seepage and worsening conditions for corrosion of the reinforcement, and all increase the potential for cracking or total failure.

Solution to the Issue

Complete demolition of buildings built with RAAC would not be practical or economical; therefore, engineers are looking to other solutions, as below. Some of the best engineering solutions include:

- Adding secondary supports, such as steel beams, can enhance weak panels.

- Using lightweight backup materials, such as timber, directly supports panels.

- Installing passive fail supports, which would mitigate total collapse as a result of a URAC panel failing.

- Replacing existing panels with contemporary concrete products is in a greater strength of concrete and general durability.

- Proper maintenance and periodic inspections also play a key role in preventing unexpected failures in structures that still contain RAAC.

In Conclusion

Reinforced Autoclaved Aerated Concrete was once a revolutionary idea that aimed to make construction faster and more affordable. However, as time has shown, its lightweight nature comes with certain trade-offs, especially in terms of durability and long-term stability.

With today’s advanced construction materials and chemical technologies, builders can overcome these limitations and ensure that the strength of concrete meets modern safety standards. At Sakshi Chem Sciences, we remain committed to empowering the construction industry with innovative chemical solutions that make every structure stronger, safer, and built to last.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.