Steel and concrete are practically a match made in construction heaven – strong, long-lasting, and universally used to construct everything from bridges to highways to buildings to dams.

Unfortunately, even this dynamic duo eventually succumbs to the ravages of time and nature. One of the biggest threats lurking inside these structures is corrosion of steel reinforcement within concrete.

Table of Contents

Left unattended, corrosion will weaken the structure quietly from the inside, eventually causing cracks, crumbling, or a structural collapse. Let’s take a look at what corrosion is, how it occurs within reinforced concrete, and most importantly, how to prevent it.

What is Corrosion?

Corrosion is simply nature’s way of breaking down metals. Corrosion is a chemical process by which a metal (steel) reacts with moisture and oxygen (and other chemicals), to form rust, or other products like metal oxides or sulphates.

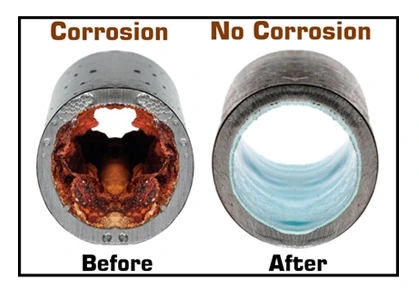

When the steel inside concrete experiences corrosion, it becomes reddish brown and brittle. Over time the corrosion process causes the steel to lose strength and become scaled.

The tricky part about rust is it expands; the expansion outwardly pushes on the surrounding concrete causing cracking, bulging, and eventually breaking apart the protective shell.

Why Does Steel Corrode in Concrete?

Concrete is a good protector. Its high alkalinity provides a passive layer around the steel reinforcement and protects it from corrosion, for the most part.

However, once that protection is compromised by something like water or chloride ions (salt in particular), the trouble starts.

Let’s see what the process looks like:

Initiation – Chloride ions or carbon dioxide can penetrate through the concrete cover and break the passive protective film on the steel.

Propagation – The steel begins reacting with oxygen and moisture, converting into rust.

Expansion – The rust takes up more volume than the original steel, leading to internal pressure.

Deterioration – Elements of the original structure crack, peel off (spalling), and the steel weakens eventually.

If left untreated, the corrosion of reinforcement steel ultimately causes the integrity of the whole structure to be compromised.

Common Causes of Corrosion in Concrete Structures

There are a number of ways that corrosion of reinforcement steel can be allowed to enter concrete structures:

1. Chloride Contamination

This sort of contamination is the number one cause of corrosion of steel reinforcement. Chlorides come from:

- Seawater or sea spray in coastal regions.

- De-icing salts used on roads in winter.

- Industrial wastewater from factories.

- Contaminated or chloride-laden aggregates (rocks/sand) or water that were used during concrete mixing.

- Admixtures that contain salts.

Once chlorides are introduced to the concrete and are in solution, they can diffuse through “pores” no matter how small. They are water-soluble this way. The water that is used in mixing concrete may contain chlorides.

Once there, the chloride ions can walk through any tiny pore in the concrete due to capillary action. Further freeze-thaw cycling will then push these salts deeper and deeper until they access the steel reinforcement.

2. Carbonation

This is a slow process in which carbon dioxide in the atmosphere reacts with the calcium hydroxide in the concrete, lowering its pH. A lower pH means a reduction in the protective alkaline barrier around the steel, and, in turn, corrosion.

3. Improper Construction Practices

- Excess water in the concrete mix.

- Underlapping concrete cover over steel.

- Inadequate compaction or curing.

- Use of untested or poor-quality products.

All of these practices result in concrete that is more porous and less protective.

What Happens When Steel Rusts Inside Concrete?

Rusting of steel is not merely a surface issue. The rust that develops expands about 2 to 6 times greater than the original steel. This internal pressure can lead to:

- Cracking and widening of joints.

- Delamination (separation of layers in the concrete)

- Spalling (pieces of concrete falling off )

- Reduced load-carrying capacity.

All of these symptoms can lead to partial or total failure of the structure – this is especially scary at bridges, parking decks, high rises, and marine structures.

How Can We Stop Steel from Corroding in Concrete?

We are lucky that there are many effective ways to minimize or avoid corrosion. Let’s take a closer look:

1. Use of Protective Coatings

Cement-polymer composite coatings: These develop a chemical barrier around the steel that is effective at maintaining an alkaline environment that does not promote rust.

Fusion bonded epoxy (FBE) coatings: These are applied as powders and melted onto the steel creating a thick, corrosion-proof layer of material.

But be careful—coating must remain untouched during delivery and installation.

2. Corrosion-Resistant Reinforcement Bars

Some steel is made with elements like chromium, copper or nickel elements to reduce corrosion. This type of steel will be more expensive, however, its lifetime benefits are unsurpassed, especially in aggressive environments.

3. High-Quality Concrete Mix

Good protection starts with the mix. If you utilize low water-to-cement ratio concrete you will create a denser, lower porosity concrete which will mitigate moisture and chloride ingress from the environment. Supplementary cementitious material like:

- Fly ash

- Ground granulated blast furnace slag (GGBFS)

- Silica fume

- Pozzolana

These supplementary materials can add added durability against permeability concerns.

4. Adequate Concrete Cover

Always ensure adequate cover (distance between the steel and surface of the concrete). More cover means more time before the environment has access to corrosive agents. Construct spacers and guides to help you get this right before you pour.

5. Testing Materials Prior to Being Utilized

It is essential that every ingredient (especially water, aggregates and admixtures) should be tested for chloride content prior to use. Using salty ‘ingredients’ during the mixing process will inherently seed corrosion into your concrete from day one.

6. Routine Maintenance and Inspection

Even the most well-crafted structures deteriorate over time and incorporating regular inspections enables early recognition of corrosion processes such as cracking, staining, and delaminating—prior to catastrophic damage.

Advanced inspection techniques like half-cell potential analysis, ground-penetrating radar, or core sampling can all assist in the early detection of corrosion processes.

Corrosion Inhibitors Add Value

Corrosion inhibitors are special proprietary chemical additives either entrained within concrete or applied on the surface, that form a protective membrane over the reinforcement or chemically reacts with the reinforcement to limit corrosion. Corrosion inhibitors include:

- Anodic inhibitors (e.g. calcium nitrite) – react with steel and create a protective film

- Cathodic inhibitors (e.g. sodium benzoate) – slow down the rate of the cathodic reaction

- Mixed inhibitors (e.g. lithium-based) – protect or slow down the anodic and cathodic regions.

FRP Bars As a Non-Corrosive Option

Fiber-Reinforced Polymer (FRP) bars are composed of fibers that include:

- Carbon (CFRP)

- Glass (GFRP)

- Aramid (AFRP)

- Basalt (BFRP)

FRP bars will not rust. FRP bars are currently (3) times lighter, and resist many chemicals and moisture. FRP is becoming a more commonplace design and construction feature for the retrofitting and strengthening applications for damaged structures.

However, there are disadvantages of FRP bars including:

- Lower stiffness (more flexible than steel)

- Poor UV resistance and limited heat resistance

- Very low bond strength between layers

- High initial cost and little field experience

- Even with these considerations FRP bars are terrific for marine structure, bridges, and in de-icing conditions.

The Global Cost of Corrosion

NACE (National Association of Corrosion Engineers) published a recent study that indicated the total cost of corrosion in the world to approximately 3.4 percent of global gross domestic product (GDP).

In India the same number was 4.2 percent. It is fair to say that an amount of this is associated with corrosion in infrastructure, specifically steel-reinforced concrete.

This is an example of why we must be mindful not only of building, but also of building smart and ultimately building long-lasting quality infrastructure.

Final Thoughts: Fighting Corrosion is a Wise Investment

Mild steel reinforcement corrosion in concrete is not only a technical issue, it is also an economic issue and subsequently a safety issue.

Failure to manage and address corrosion will lead to higher repair costs, shorter working life for the structure, and put our infrastructure at risk of catastrophic failure.

Using a combination of smart materials, protective measures, periodic assessment, and preventive measures such as high-performance concrete and corrosion inhibitors, we can maximize the longevity of our structures and ensure they are still standing strong for our children many years from now.

Investing in corrosion prevention today means saving on repairs—and potentially saving lives—tomorrow.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.