If you have done any kind of work with mortar, whether it be laying bricks, rendering walls, or installing tiles, you usually know how important it is to get consistency right. It is one of those things that sounds easy enough, but can seriously enhance or ruin… a project.

Table of Contents

If the mortar is too wet, it will not hold shape, may crack, or be unable to hold the bricks’ weight well. If it is too dry, it will be difficult to work with, will not stick, and therefore will become difficult to adhere. This consideration of consistency is an important one for any mason, engineer, or contractor to comprehend.

Let’s break it down and see exactly what mortar consistency means, how we can test consistency, what affects consistency what we are able to do to get the mixture suitable for a variety of construction tasks.

What is Mortar Consistency?

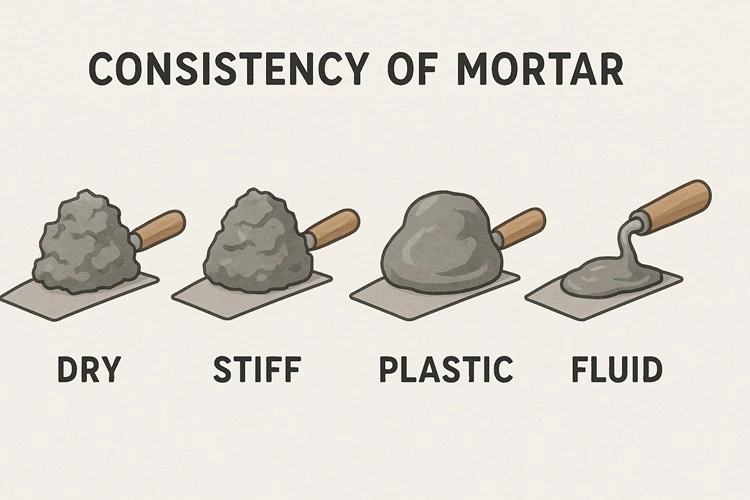

In the most basic terms, mortar consistency means how stiff or runny the freshly mixed mortar is; more particularly, it relates to how the mortar behaves, and texture; how easily it spreads, sticks, but mostly, how well it holds shape.

At first glance, you may think this is just a matter of trying different ratios of dry mix to water; however, in practice, it is so much more than that. It can be affected by a range of things, including:

- What it’s used for (bricklaying, rendering, tiling, pointing, etc.)

- Surface characteristics (smooth vs rough, dry vs damp)

- Weather conditions (heat, cold, wind, humidity)

- Tools and methods (manual vs machine application)

- Mix composition (type of cement, sand, additives)

This is complicated, which is why many seasoned masons rely on feel; they develop a feel over time for what the “right mix” feels like on the trowel.

For those new to the trade, this can be a source of confusion, but science has provided us with measurable ways to describe and assess the consistency of the mortar.

How to Measure Mortar Consistency

Gone are the days when a quick visual check or guess was good enough. Nowadays, we have reliable tests that take the guesswork out of the mix.

1. Flow Table Test (ASTM C1437 / EN 1015-3)

The flow table test is one of the more popular methods. A cone of fresh mortar is placed on a table that is then dropped several times. The spread (or flow) of the mortar is simply measured. For general use, such as bricklaying, ideally flow is a percentage spread of 105 – 115%.

2. Plunger Penetration Test

In this case, a typical, standard plunger test is performed with the mortar – the farther the plunger can descend into the mix, the softer it is.

We can assess the mortar to see if it’s either too wet or too dry, with 10 – 15 mm being consistent with stiff-type mortar and 30 – 40 mm being a fluid-type mortar.

3. Slump Test

Slump tests are usually used more with concrete; however, they can be applied in some cases in mortarwork, particularly when working with self-leveling compounds or generally fluid mixes.

By applying these methods of testing, we can have a means of consistency that is not subjective, and can become a value that we drive forward with, both for better quality control and repeatable results.

Matching consistency to the job

The “perfect” mortar consistency is based on how you will be applying the mortar. Here are some examples:

4 Bricklaying and Block Work

In this example, the mortar should be stiff, but workable – think of a smooth, buttery experience. As we build our wall, it must hold its shape and be held under the weight of the brick, yet it must also be spreadable. Flow values for this will range from 130 – 150 mm.

5. Rendering and Plastering

When applying mortar to walls, a more liquid mix will assist in problem-free applications. The consistency of plaster is easier, smoother, and straightforward, but the mix should not be so sloppy that it runs and drips. Expect a flow between 160 – 180 mm.

6. Tiling

Different types of tile adhesives have various consistencies based on the size of the tile, whether it will be used on a wall or floor, and the substrate it will be applied to.

It is not unusual for thicker mortars to contain 140–160mm (1/4–1/2 in.) using one of the thick mortar applications for floors.

Slightly more fluid versions of the same material are often useful for walls, so you can ensure the adhesive in those applications can bond appropriately.

7. Pointing and Repair Work

Pointing and repair work can use one of the driest mixes you will handle, with moisture content often described as “earth-damp.” Again, this gives you a nice mix that allows precise placement without slumping or bleeding into adjacent surfaces.

8. Self-Levelling Mortar

At the other end of the scale, self-leveling compounds must be extremely fluid, often having flow values that exceed 250mm, so that the compound can spread and settle into places without the need for a trowel.

Environmental Factors That Affect Mortar Consistency

Outside influences have a huge effect on the effectiveness of a mortar mix. This is true in all areas of construction, but various environments sometimes have huge effects on how a mix behaves.

● Hot and Dry Weather

In hot climates, mortar can dry out very quickly due to evaporation, and this can result in weaker bonds and, in extreme cases, can result in premature cracking.

To avoid this, masons resort to adding more water, and while this may lessen slumping, there is still added risk.

Some of the previous experimentations involve additives such as HPMC (Hydroxypropyl Methylcellulose), which, without too much modification of the water-cement ratios, stay wetter in the mixing bowl.

● Cold Conditions

In cold weather, mortar takes longer to set, and changing the consistency of the mortar will not help you here. You will either need special winter additives or insulated curing to get a good bond.

● Windy Conditions

Wind can dry the surface of the mortar while the rest of the mortar is still wet. Think of it as a crust that looks set but actually isn’t. This is referred to as a “false set,” and it can be difficult to control. Shielding the area and possibly making slight adjustments to the mix will help in some cases.

How Modern Additives Can Help

In the past, the only way to adjust the consistency of the mortar was to alter the amount of water, which more often than not was a compromise between strength and workability.

Modern chemical additives can help keep good consistency without adding too much water. Following are some interesting developments:

● Water Retention Agents (such as HPMC)

Water retention agents retain water inside the mix longer, extending the period available to work with the mortar for a bit longer—2-3 hours in some cases. This results in less waste, increased time to finish details, and better bonding.

A real-world example is an overseas project in the Middle East, where the heat was so dire that it dried out the mortar prior to application.

After switching to a formulation with Kemox HPMC, the crew experienced less cracking, better bonding, and increased workability, even without adding excess water!

● Redispersible Polymer Powders (RDP)

These give the mortar better cohesion, as well as decrease the amount of water required to achieve the proper consistency. So it is a win-win for both workability and durability.

● Thixotropic Additives

These unique ingredients provide the mortar with the ability to act differently against the force of gravity. While working with tools, the mortar becomes fluid in nature.

But, at rest, the mortar will stabilize or firm up, allowing you to feel confident that the mortar will stay in place without slumping to the floor. This is desirable when doing vertical tile work.

Consistency Over Time: Open Time and Board Life

Consistency of mortar can change over time, even after it has been mixed, because water evaporates and the cement starts the setting process. The words “open time” or “board life” refer to how much time you have for usable mortar.

When using traditional mortar mixes, it used to take 30-60 minutes for the mortar to completely harden, so you were either hurried to finish or had to mix small batches of mortar, both of which could lead to sloppy workmanship.

Additives like HPMC have also changed the open or work time with sandstone. You can have hours of time to produce a usable mortar mix, which can assist in comfort, help to reduce pressure, and produce better quality workmanship.

Recommendations for Achieving the Proper Consistency

There are some things you can do to make sure your mortar mix has the proper consistency.

Stick to the Manufacturer’s Instructions! Always adhere to the water-to-mix ratios written on the product bag or technical sheet.

Weigh and Measure Accurately! Only use measuring buckets or weighing scales to weigh your ingredients. It’s easy to miss the mark and create discrepancies by “eyeballing” the mix.

Consider the Sand’s Moisture Content! If your sand is wet, then you may need less water.

Mix Thoroughly! Consider the time needed to adequately mix water, cement, and additives.

Make Adjustments All Day! On particularly hot or cold days, make smaller amounts, or work in shaded or protected spaces.

Conclusion

Good worker practice in masonry, rendering, and tiling is reliant upon mortar consistency. Mortar consistency affects everything from the ease of application to the bond strength to the longevity of the product.

Older generations relied on feel and instinct to ensure mortar consistency, and today’s builders employ tools, techniques, and now additives that allow them precision and control.

It has never been easier! Additives like HPMC, RDP, and thixotropic agents make producing the perfect mix easy as pie for any job in any environment.

Ultimately, applying mortar consistency is a science and an art. With the right knowledge, testing, and material, you can rest assured that every batch of mortar provides the strength, beauty, and durability of your project, brick by brick.