Description

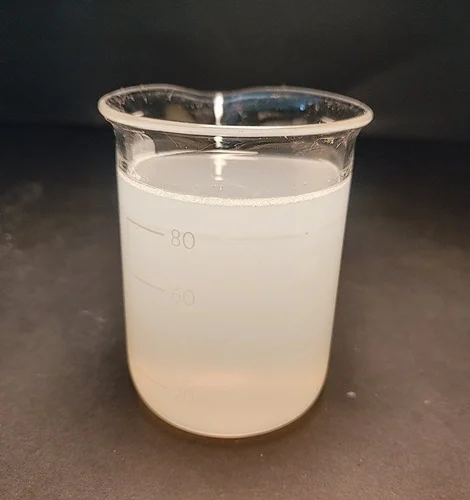

ADDAGE FOAMING AGENT (SYNTHETIC) is a superior and economical product specifically manufactured to produce Cellular Lightweight Concrete (CLC) Block and Lightweight Foam Concrete.

Produced by Addage, this synthetic foaming agent will produce a long-lasting and stable foam that will allow for the production of lightweight concrete with no loss of strength.

In addition, it is designed for consistent performance regardless of the water quality and temperature conditions. Thus, the ADDAGE FOAMING AGENT (SYNTHETIC) offers a great deal of value in terms of reliable foam generation, control over foam density, and improved workability when making Foamed Concrete.

Key Features:

The ADDAGE FOAMING AGENT (SYNTHETIC) contains a high concentration of foaming agent, which provides significant air entrapment at low dosages. When combined with water, it forms a stiff and stable white foam that will increase the volume of the solution approximately 20 to 25 times, making it a very economical material for large volume production.

The foam produced is uniform and stable; therefore, it will not collapse as readily as some other foaming agents during the mixing, pumping, and placement procedures.

Furthermore, ADDAGE FOAMING AGENT (SYNTHETIC) maintains foam integrity through a wide range of temperatures and water quality, making it usable at many different types of construction sites. The ADDAGE FOAMING AGENT (SYNTHETIC) works well with all types of Portland Cement and blends well into standard production processes for CLC.

Technical Specifications

- Brand: Addage

- Form: Liquid

- Usage/Application: Commercial

- Grade Standard: Technical Grade

- Packaging Sizes: 50 Kg & 200 Kg

- Packaging Type: Can & Barrel

- Minimum Order Quantity: 50 Kg

Recommended Applications

ADDAGE FOAMING AGENT (SYNTHETIC) is primarily used in the manufacturing of CLC blocks and lightweight concrete, where controlled density and consistent foam quality are critical. Typical applications include:

- CLC block production plants

- Lightweight foamed concrete blocks

- Non-load bearing wall elements

- Thermal and sound insulation blocks

- Lightweight filling and void filling applications

- Produces stable, uniform, and stiff foam

- High foam expansion ratio of 20–25 times

- Enables production of low-density lightweight concrete

- Cost-efficient due to low dosage requirement

- Maintains foam stability during mixing and placement

- Improves workability of foamed concrete

- Compatible with all Portland cement types

- Performs consistently across different water qualities

- Suitable for varied temperature conditions

- Helps achieve uniform block density and surface finish

Its reliable foam structure makes it suitable for both small-scale units and large automated production lines.

Dosage Guidelines

The dosage of ADDAGE FOAMING AGENT (SYNTHETIC) depends on the desired density of the concrete, mix design, cement content, and foam generation method.

The foaming agent is diluted with water and processed through a foam generator to produce stable foam, which is then mixed into the cement slurry.

Due to its high concentration, only a small quantity is required to achieve the desired foam volume. Trial mixes are strongly recommended to optimize foam density and concrete performance based on specific production requirements.

Product Benefits

ADDAGE FOAMING AGENT (SYNTHETIC) supports efficient production while maintaining the strength and durability of lightweight concrete products.

Packing

ADDAGE FOAMING AGENT (SYNTHETIC) comes in cans of 50kgs and barrels of 200kgs, suitable for both pilot-level production and large quantities in industrial use. The method of packaging ensures that our product is stored safely, handled easily, and has minimal loss during transportation and usage.

Storage & Shelf Life

ADDAGE FOAMING AGENT (SYNTHETIC) must be kept in a dry location with no direct sunlight or extreme temperatures. Placing your container stored tightly sealed when not in use will help prevent contamination and evaporation of the product.

When stored according to the manufacturer’s instructions, the foaming capabilities of ADDAGE FOAMING AGENT (SYNTHETIC) will remain operational for its duration of shelf life.

Safety Precautions

Safety procedures should be exercised while working with ADDAGE FOAMING AGENT (SYNTHETIC). Protect yourself by avoiding direct eye contact or prolonged skin exposure. Use gloves when necessary.

Rinse with clean water if you get any on your skin or in your eyes. Do not allow children access to this product, and do not ingest the usage materials.